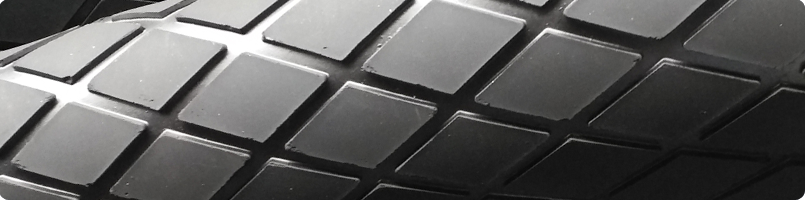

DIAMOND LAGGING RUBBER SHEETS

Lagging is the term used to describe the application of a coating, cover or wearing surface which is sometimes applied to Diamond shells. Lagging is often applied in order to extend the life of the shell by providing a replaceable wearing surface or to improve the friction between the belt and the Diamond. Notably drive Diamonds.

Diamond lagging rubber sheets are used to eliminate belt slippage, increase Diamond life, improve water shedding and boost productivity. We provide the highest quality of Pulley Lagging Rubber Sheets at the affordable price range.

|

Diamond Lagging Rubber Sheets |

|||||||

|

Features |

Gutter less design for cleaner compatibility reduces belt vibration and cleaner chatter for standard |

||||||

|

Applications |

To help eliminate slippage, increase Diamond life and to improve production. |

||||||

|

Finish Type |

Square and diamond design Diamond lagging sheet |

||||||

|

Standard Thickness |

6 mm to 40 mm |

||||||

|

Standard Length |

10 Mtr, 33 Ft, 11 Yard |

||||||

|

Standard Width |

1.2 / 1.4 / 1.5 Mtr, 48″ / 54″ / 60″ inches |

||||||

|

Color |

Black |

||||||

|

Technical Specification: |

|||||||

| Code |

Specific Gravity |

Hardness (+/- 5) |

Tensile Strength |

Elongation |

Abrasion |

Temperature |

|

|

Gm/cm³ |

Shore A |

Kg/cm² |

% |

mm³ |

°C |

||

| STANDARD |

ASTM D297 |

ASTM D2240 |

ASTM D412 |

ASTM D412 |

ASTM D5963 |

— |

|

| ABE 65117PL |

1.17 |

65 |

115 |

450 |

280 |

-25 to +70 |

|

| ABE 60130 PL |

1.30 |

60 |

50 |

300 |

250 |

-25 to +70 |

|

|

|

|

|

|

|

|

||

We have been in the forefront of supplying industrial rubber products since 1980.

We providea variety of Anti-Skid Rubber Mats for multipurpose use. The primary objective is to provide a durable non-skid doormat. While using Flooring mats, slippage or creeping of Floor mats has always been a problem in wet or dry applications. Our various anti-skid mats are the best solution for it. Our mats are excellent in shock absorption and slip resistance as well as providing improved walking comforts. Flooring mats with anti-skid ridges prevent slips & falls and come with a protective, non-stick finish to make cleaning quick and easy. These Mats, Rubber Roll Sheets are available in various compounds depending on their indented use.

|

Specific |

Hardness |

Tensile |

Elongation |

Tear Strength |

Temp. |

Colour |

|

|

gm / cm³ |

Shore A |

(min) |

(min) |

kg / cm² |

°C |

||

|

FINE RIB FS65 |

1.5 |

70 |

50 |

250 |

20 |

-30 to 80 |

Black |

|

FLAT RIB LS 65 |

1.5 |

70 |

50 |

250 |

20 |

-30 to 80 |

Black |

|

DIAMOND |

1.5 |

70 |

50 |

250 |

20 |

-30 to 80 |

Black |

|

BROAD RIB CR 65 |

1.5 |

70 |

50 |

250 |

20 |

-30 to 80 |

Black |

|

CHECKERED CD 65 |

1.5 |

70 |

50 |

250 |

20 |

-30 to 80 |

Black |

|

COIN MATS 65 |

1.5 |

70 |

50 |

250 |

20 |

-30 to 80 |

Black |

|

AMOEBA MAT |

1.5 |

70 |

50 |

250 |

20 |

-30 to 80 |

Black |