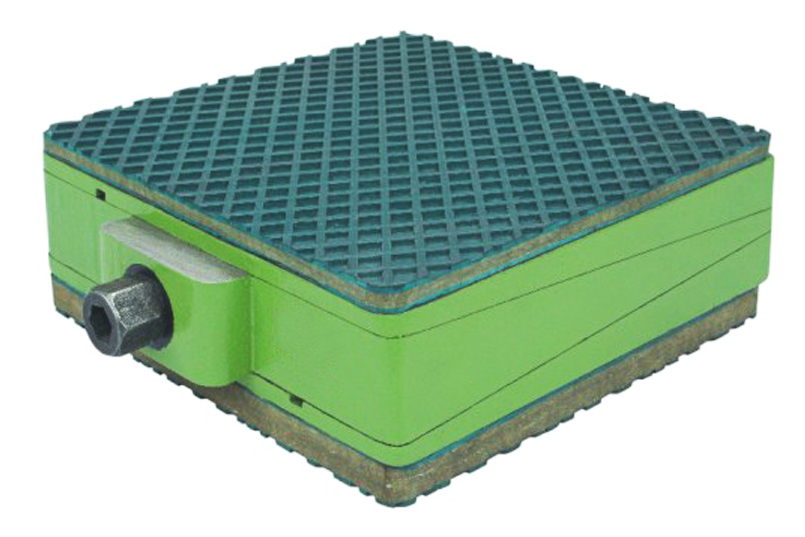

PRECISION WEDGE MOUNT

Application

Precision Wedge Mount is designed for applications requiring passive damping and installation of high load equipment. The design incorporates a high-precision levelling system for easy height adjustment. The large supporting surface of the wedge mounts permit optimum foundation support and rigidity. High solidity and equally high vibration insulation is obtained through the addition of selected insulating plates. The rectangular shape of the Mount is yet another advantage. While providing greater resistance to machine “walking” than circular mounts, the straight leading-edge surface on the rectangular mount has proven to be more geometrically stable. This helps eliminate pad roll and entrapment of coolants and oils beneath the pad. In addition, each isolation pad is engineered to possess an exceptionally high coefficient of friction that also prevents machine “walking”.

Advantages :-

1. Reduced shock and vibration

2. Heavy Duty machinery mount system

3. Two height ranges in one mount

4. Fast, Precise leveling of machine & prevent machine walking

5. Good stability due to non slip character of plates

6. Highly effective insulations in the active and passive range. In particular when used on upper floors.

7. Increased equipment life

8. Simplified machine installation

9. Elimination of anchor bolts

10. Uneven floors accommodated

11. Horizontal impact capabilities

Applications :-

Injection Molding Machines, Pad Printers, Machine Tools, Presses, Stamping Machines, Boring Machines, General Multi-Purpose Machines with Long Beds, Shears, CNC Lathes, Surfaces and Cylindrical Grinders, Drilling & Milling Machines, Machining Centers, Transfer lines.

|

TYPE

|

LOAD kgs

|

LENGTH mm

|

WIDTH mm

|

HIGHT in intermediate position

|

RANGE OF ADJU.

mm |

|

PM-0-A

|

500

|

100

|

60

|

57

|

8

|

|

PM-0-B

|

750

|

100

|

60

|

67

|

8

|

|

PM-0-C

|

300

|

100

|

60

|

67

|

8

|

|

*PM-0-E

|

1400

|

100

|

60

|

40

|

8

|

|

PM-1-A

|

900

|

150

|

75

|

65

|

10

|

|

PM-1-B

|

1200

|

150

|

75

|

75

|

10

|

|

PM-1-C

|

780

|

150

|

75

|

75

|

10

|

|

*PM-1-E

|

3500

|

150

|

75

|

44

|

10

|

|

PM-2-A

|

1950

|

200

|

100

|

70

|

10

|

|

PM-2-B

|

2200

|

200

|

100

|

80

|

10

|

|

PM-2-C

|

1400

|

200

|

100

|

80

|

10

|

|

*PM-2-E

|

5900

|

200

|

100

|

55

|

10

|

|

PM-3-A

|

3200

|

200

|

200

|

70

|

12

|

|

PM-3-B

|

4400

|

200

|

200

|

80

|

12

|

|

PM-3-C

|

2800

|

200

|

200

|

80

|

12

|

|

*PM-3-E

|

12000

|

200

|

200

|

55

|

12

|