PVC CURTAIN

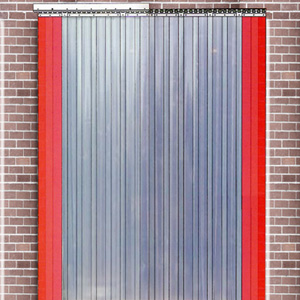

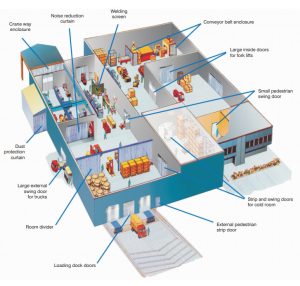

Why Use SRP PVC Strip Curtain?

↬ Energy savings and temperature control

↬ Employee comfort and protetion

↬ Separation of work areas

↬ Safety and visibility

↬ Noise, dust and pollution control

↬ Prevention of birds, insects and rodents

↬ Economical and practical

↬ Toughness, durability, and resilience

↬ Easy traffic flow, easy installation, and easy maintenance

Benefits of using SRP PVC Strip Curtains

↬ Can be installed in minutes

↬ Consesrve conditioned air, even in high-activity areas

↬ Reduce heating and refrigeration costs

↬ Reduce noise levels

↬ Easy to clean and maintain

SRP PVC Strip Curtain

Featuring the SRP Strip Curtain and bulk PVC strip rolls world’s #1 brand of PVC strip products.

Quality

Made from 100% pure virgin compounds, our PVC strips are known worldwide for their clarity, flexibility and stability.

Safety

Our PVC strips feature rounded edges for safety and optional bright safety orange edge strips to highlight the edges of the door opening

|

FLEXIBLE PVC STRIP CURTAINS WIDTHS, THICKNESS AND COLOURS |

|||||||||

|

Width(mm) |

Thickness

|

Length

|

Weight

|

Colour |

|||||

|

200mm(Flat) |

2mm

|

50mtr

|

24kg

|

Blue Tint, Natural, Amber, Red, Welding Green, Black Opac, Grey Opac, Beige Opac, Milky White Opac |

|||||

|

200mm(Flat) |

3mm

|

50mtr

|

37kg

|

Blue Tint, Natural, Amber, Red, Welding Green, Black Opac, Grey Opac, Beige Opac, Milky White Opac |

|||||

|

200mm(Flat) |

4mm

|

50mtr

|

55kg

|

Blue Tint, Natural, Amber, Red, Welding Green, Black Opac, Grey Opac, Beige Opac, Milky White Opac |

|||||

|

200mm(Flat) |

5mm

|

30mtr

|

65kg

|

Blue Tint, Natural, Amber, Red, Welding Green, Black Opac, Grey Opac, Beige Opac, Milky White Opac |

|||||

|

200mm(Flat)Super polar(-50) |

2mm

|

50mtr

|

24kg

|

Natural clear tint, blue tint |

|||||

|

200mm(Flat)Super polar(-50) |

3mm

|

50mtr

|

35kg

|

Natural clear tint, blue tint |

|||||

|

200mm(Ribbed)

|

2mm

|

50mtr

|

27kg

|

Natural clear tint, blue tint, amber, red

|

|||||

|

200mm(Ribbed)Super polar(-50)

|

2mm

|

50mtr

|

27kg

|

Natural clear tint, blue tint |

|||||

|

200mm(Ribbed)

|

3mm

|

50mtr

|

39kg

|

Natural clear tint, blue tint, amber, red

|

|||||

|

200mm(Ribbed)Super polar(-50)

|

3mm

|

50mtr

|

39kg

|

Natural clear tint, blue tint

|

|||||

|

300mm(Flat)

|

2mm

|

50mtr

|

42kg

|

Blue Tint, Natural, Amber, Red, Welding Green, Black Opac, Grey Opac, Beige Opac, Milky White Opac

|

|||||

|

300mm(Flat)

|

3mm

|

50mtr

|

60kg

|

Blue Tint, Natural, Amber, Red, Welding Green, Black Opac, Grey Opac, Beige Opac, Milky White Opac

|

|||||

|

300mm(Flat)

|

4mm

|

30mtr

|

Blue Tint, Natural, Amber, Red, Welding Green, Black Opac, Grey Opac, Beige Opac, Milky White Opac

|

||||||

|

300mm(Flat)

|

5mm

|

30mtr

|

62kg

|

Blue Tint, Natural, Amber, Red, Welding Green, Black Opac, Grey Opac, Beige Opac, Milky White Opac

|

|||||

|

300mm(Ribbed)

|

2mm

|

50mtr

|

42kg

|

Natural clear tint, blue tint, amber, red

|

|||||

|

300mm(Ribbed)

|

3mm

|

50mtr

|

62kg

|

Natural clear tint, blue tint, amber, red

|

|||||

|

300mm(Ribbed)Super polar(-50)

|

2mm

|

50mtr

|

40kg

|

Natural clear tint, blue tint

|

|||||

SRP Refrigerated Truck Strip Curtain

SRP Refrigerated Truck Strip Curtain

Designed for use on the rear opening of a refrigerated truck trailer, to keep cold air from escaping during loading and unloading. Help to reduce energy costs, protect merchandise, and meet all relevant federal and international standards and regulations for use in food transport operations

Featuring heavy-duty structural aluminium hardware for years of solid service

Employs SRP HD hardware for fast, easy,secure installation

Available with Standard Smooth, Low Temperature or Ribbed PVC Strips

Optional Safety Orange PVC strips highlight the edges of the trailer opening

Models also available for side pedestrian door opening

|

SRP FLEXIBLE PVC VINYL STRIP PHYSICAL PROPERTIES |

|||||||||

|

Properties |

Standard

|

PVC Strip Grade (Normal Tempt Grade )

|

PVC Strip Grade (Freezer Tempt Grade )

|

Unit |

|||||

| Hardness (Shore-A) |

ASTM

D 2240 |

80

|

70

|

–

|

|||||

| Density |

ASTM

D 792 |

1.20

|

1.16

|

g/cc

|

|||||

| Low Brittleness Temperature |

ASTM

D 746 |

No Break upto -10′ C

|

No Break upto -60′ C

|

–

|

|||||

| Falling ball test Drop Hight : 3inch Drop Load : 3.8Kg |

ASTM

D 4226 |

No Crack observed upto 24 lb.in

|

No Crack observed upto 24 lb.in

|

lb.in

|

|||||

| Water absorption |

ASTM

D 570 |

0.16

|

0.2

|

%

|

|||||

| Tensile strenght @ 500mm/min |

ASTM

D 638 |

15

|

11

|

Mpa

|

|||||

| Light Transmission |

ASTM

D 1004 |

90

|

89.2

|

%

|

|||||

| Flammability (i) Average extend of burning (ii) Average time of burning |

ASTM

D 635 |

58 49 |

58 49 |

mm Seconds |

|||||

| Elongation at break |

ASTM

D 638 |

746

|

700

|

%

|

|||||